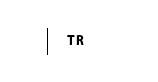

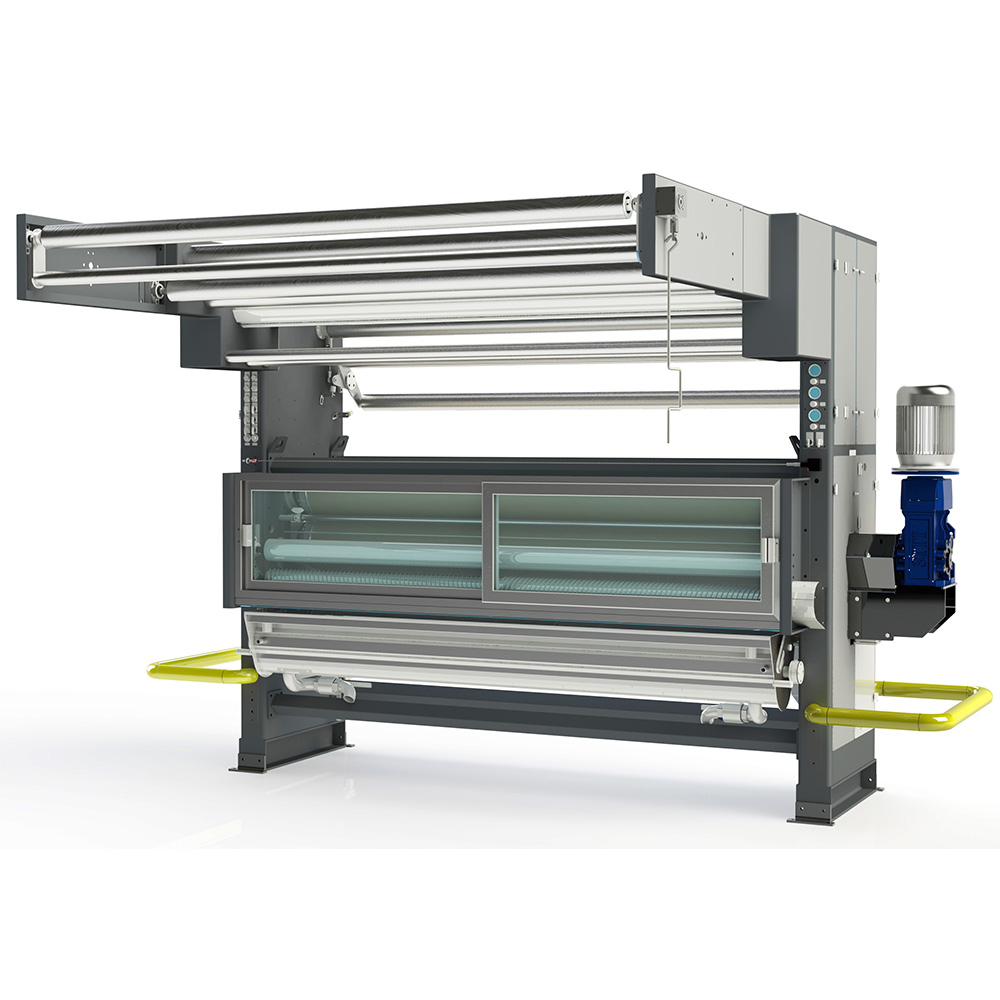

SER STENTER series; are the machines, each point of which is manufactured carefully, to provide the most efficient operational productivity possible with low energy expenses for finishing operations on the textile products.

SER STENTER series; are the machines, each point of which is manufactured carefully, to provide the most efficient operational productivity possible with low energy expenses for finishing operations on the textile products.

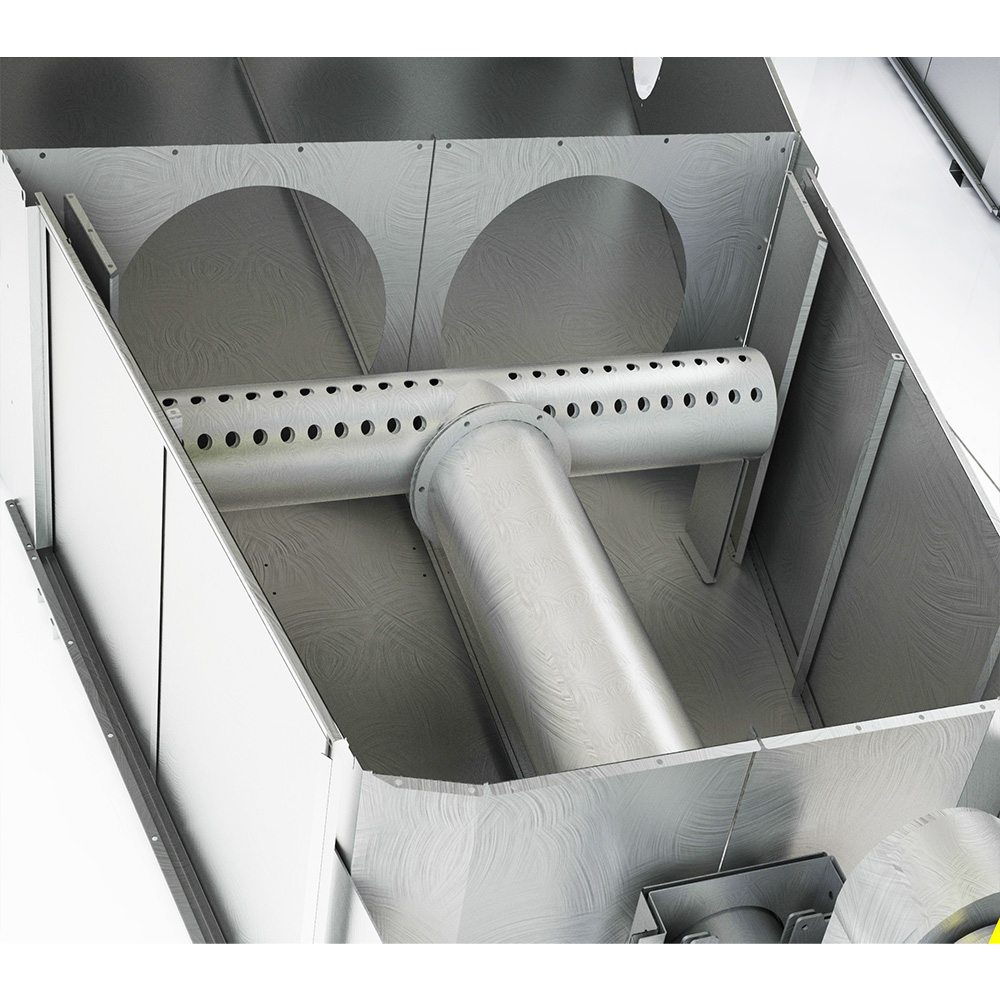

Unique chamber isolation feature, cross fan which is designed to achieve efficient us eh eoaft and homogenous air flow – provides energy saving and capacity increase in production between 8% - 15% compared to the traditional machines.

Unique chamber isolation feature, cross fan which is designed to achieve efficient us eh eoaft and homogenous air flow – provides energy saving and capacity increase in production between 8% - 15% compared to the traditional machines.

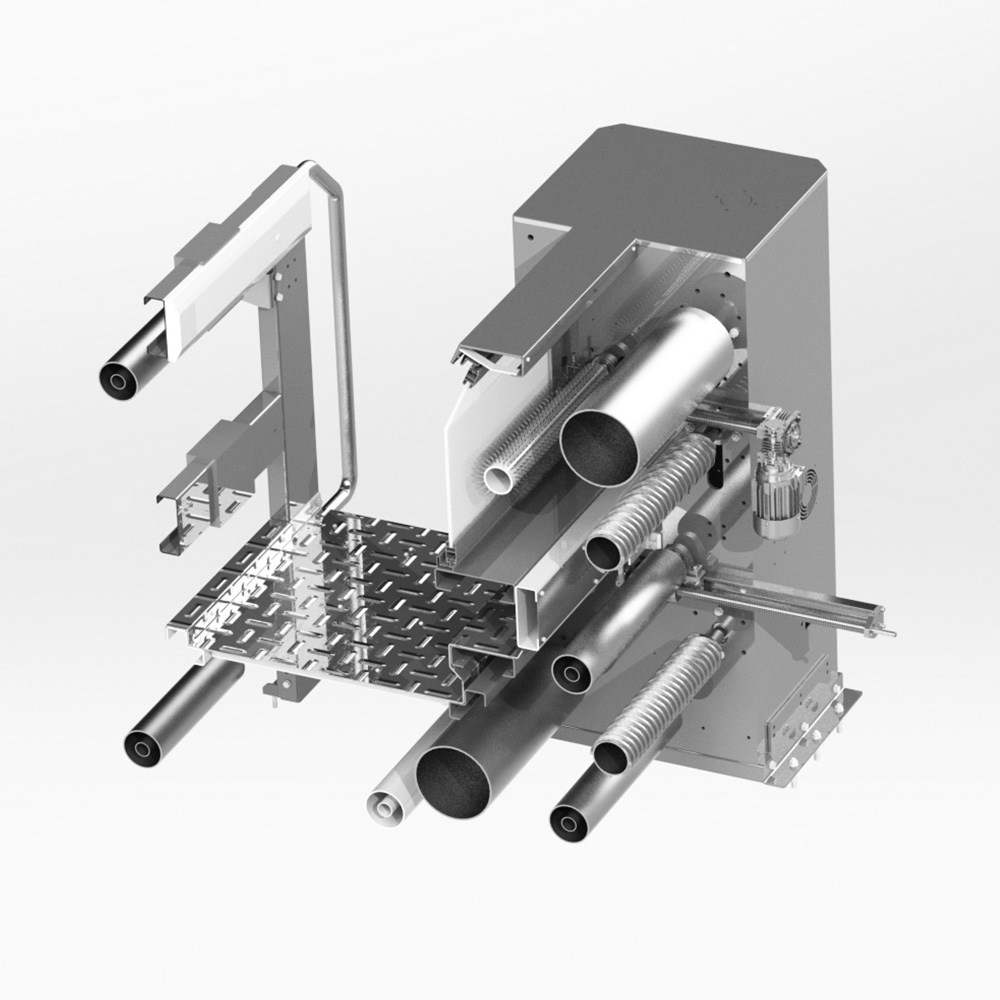

Thanks toth e heating and caiirrc ulation sections, which are placed crossly at intervals of three meters, higher air circulation gain and homogenous drying performance is achieved.

Thanks toth e heating and caiirrc ulation sections, which are placed crossly at intervals of three meters, higher air circulation gain and homogenous drying performance is achieved.

Independent air-flow system is achieved through PLC control thanks to two inverters and four fans in each chamber. Air flow in the lower and upper nozzles is independently controlled through two inverters. This way, desired fixing and feeding value is achieved on even the most

delicate fabrics.

Independent air-flow system is achieved through PLC control thanks to two inverters and four fans in each chamber. Air flow in the lower and upper nozzles is independently controlled through two inverters. This way, desired fixing and feeding value is achieved on even the most

delicate fabrics.

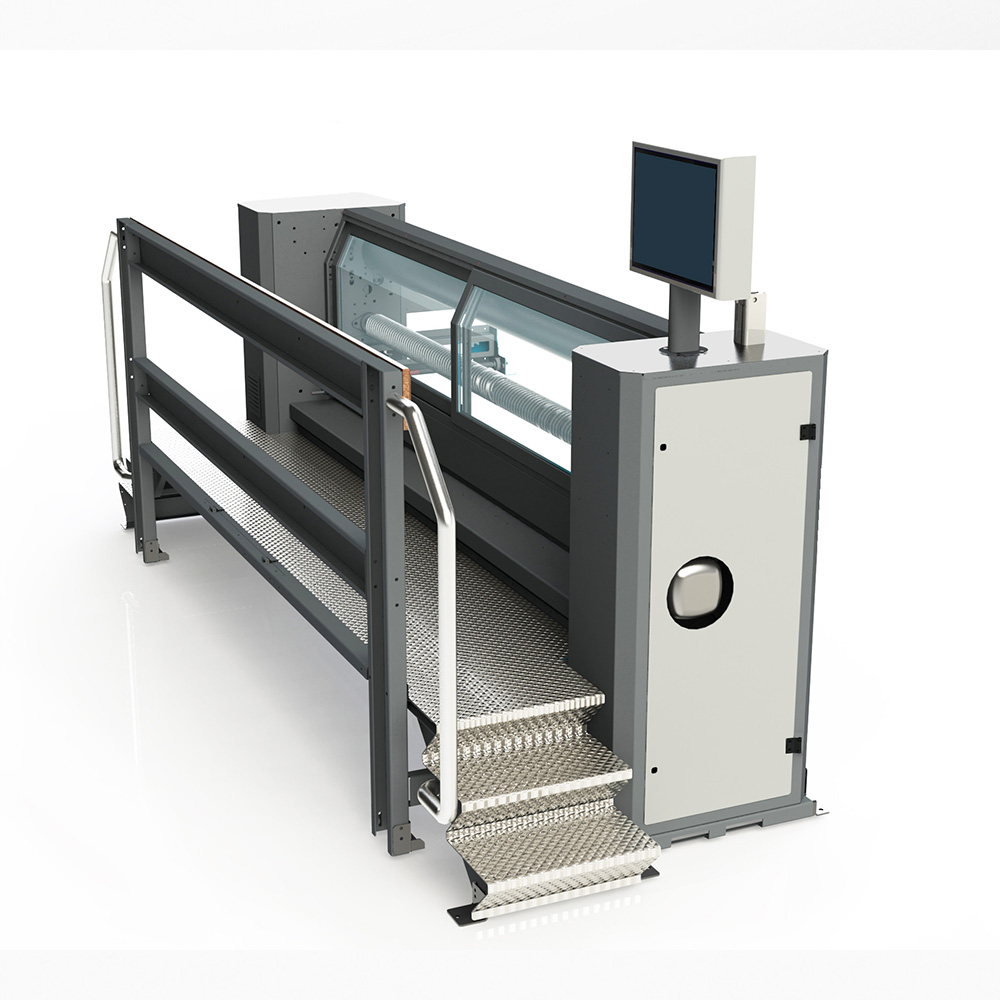

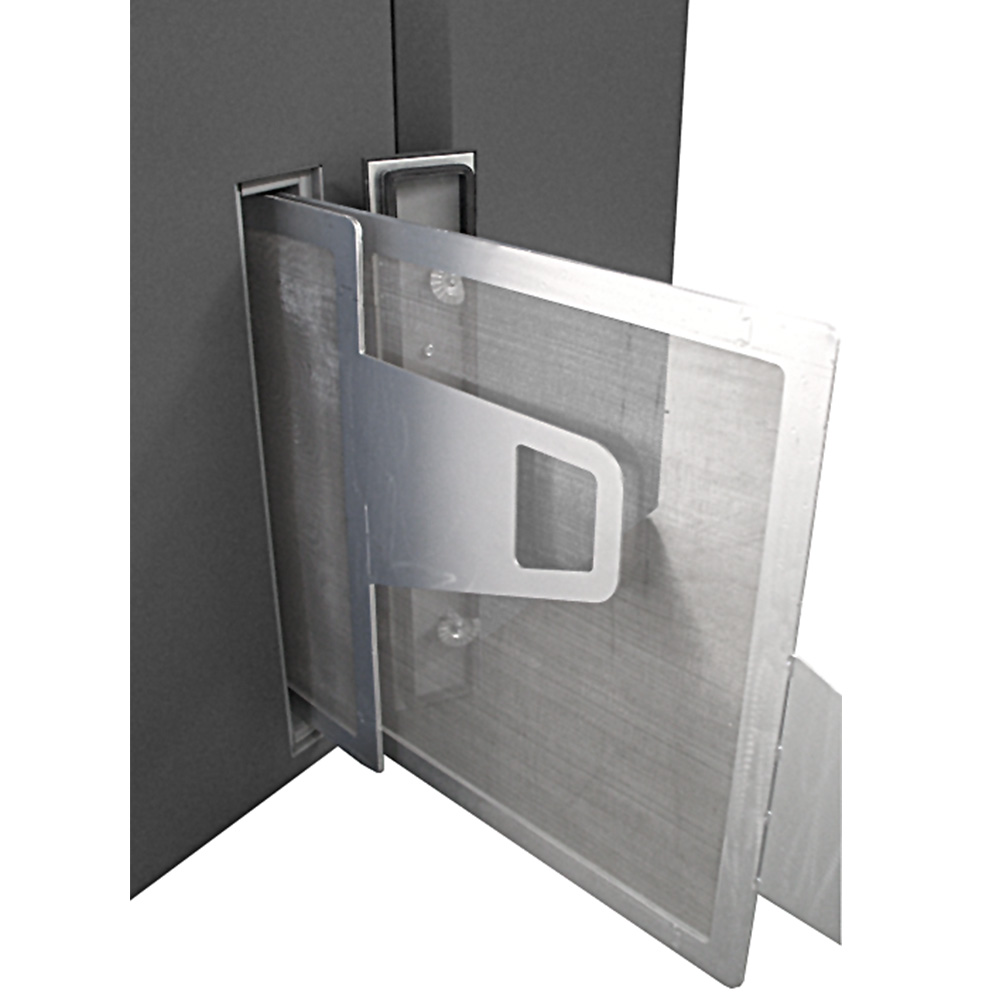

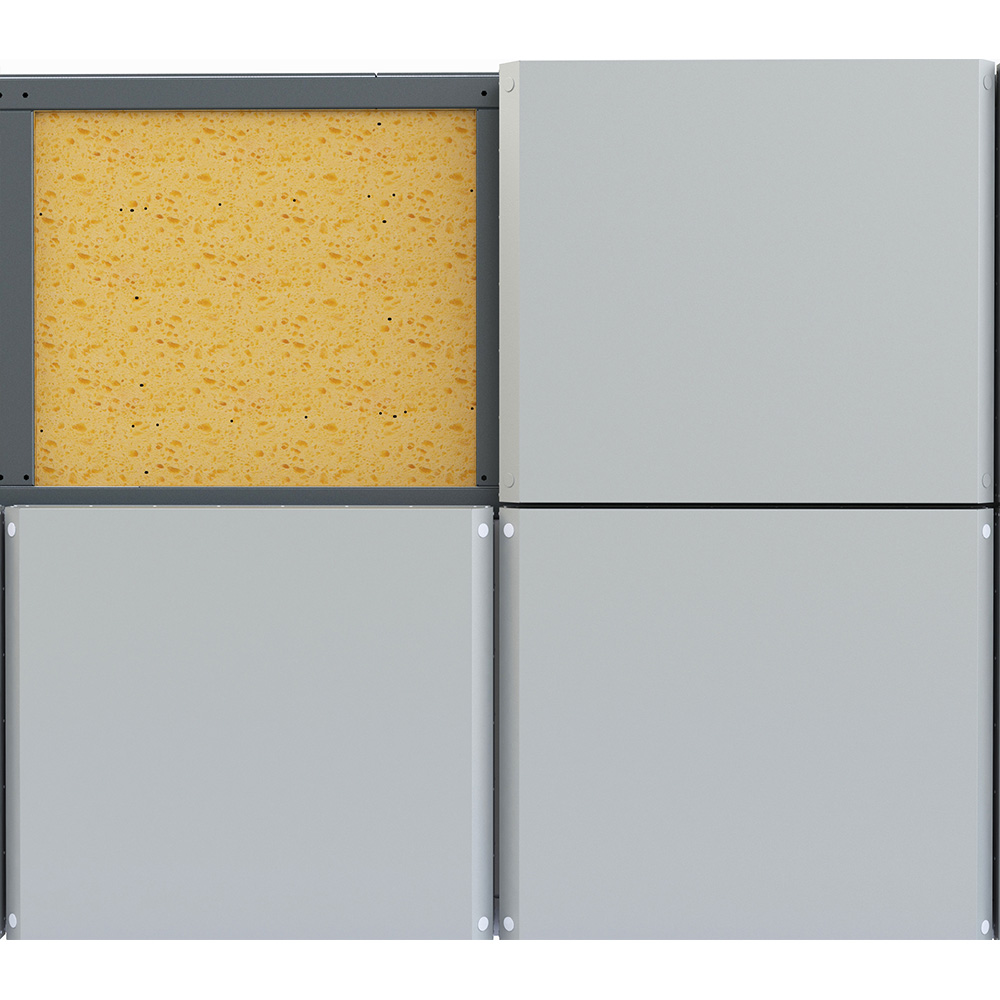

Thanks to its nozzle structure which can be easily demounted and cleaning doors, the nozzles can be quickly and easily cleaned without being removed from the machine. In addition, internal access doors on both sides of the machine provide easy access to the nozzles.

Thanks to its nozzle structure which can be easily demounted and cleaning doors, the nozzles can be quickly and easily cleaned without being removed from the machine. In addition, internal access doors on both sides of the machine provide easy access to the nozzles.

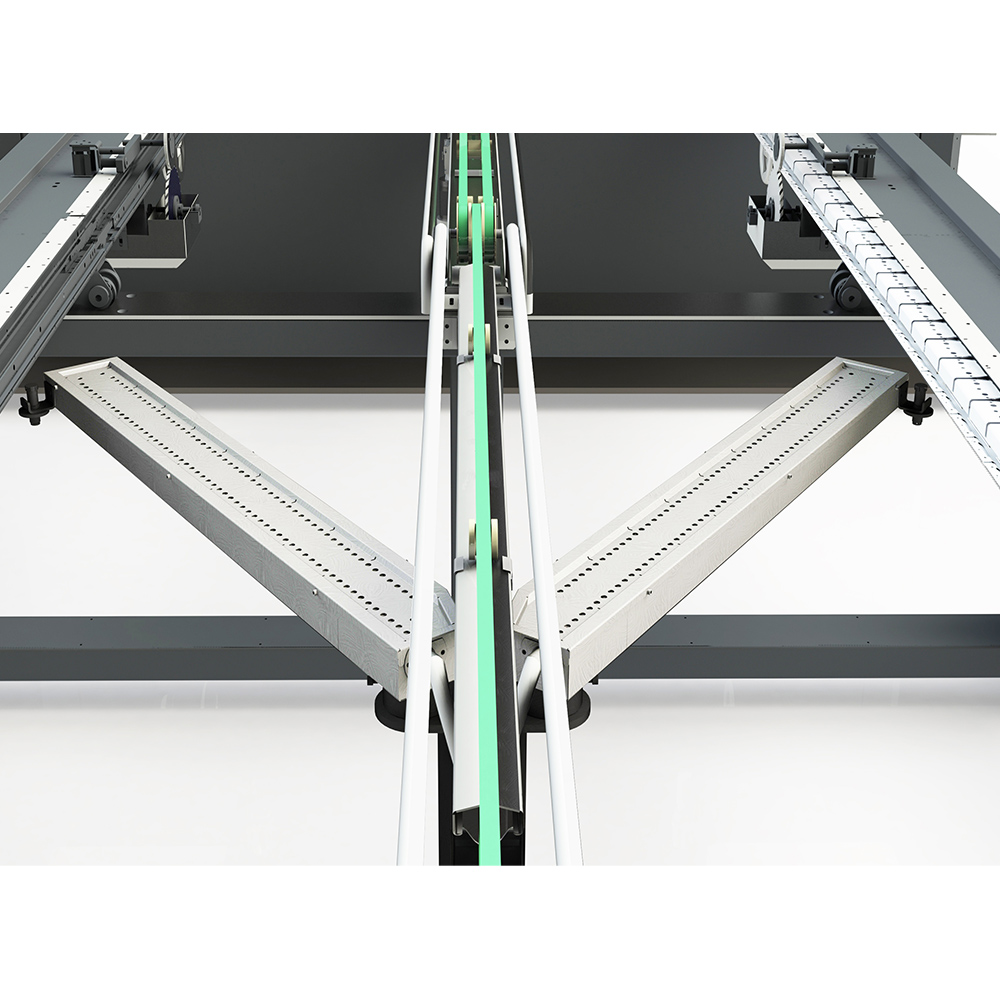

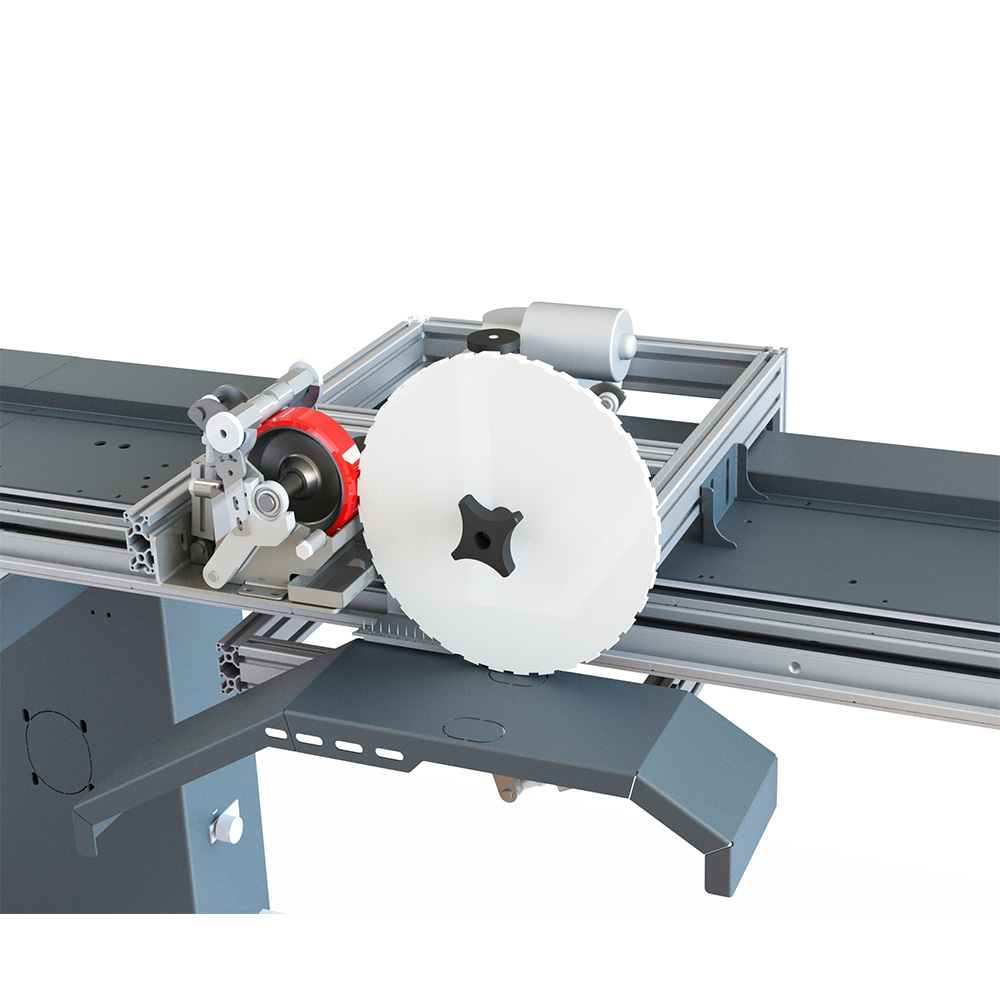

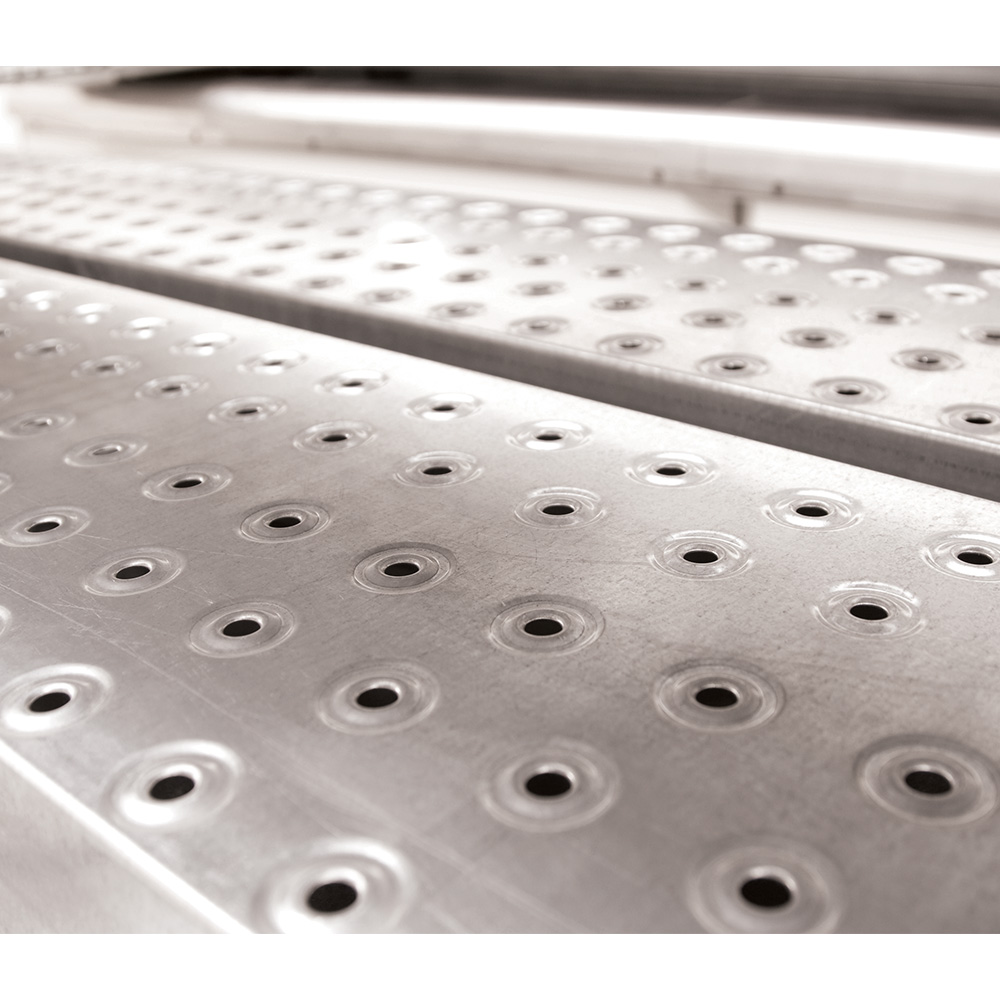

Diameters of the nozzle holes and numbers of holes are designed with flow simulation analysis and calculations to achieve the most efficient air flow. Air speeds in the nozzle holes are tested in different conditions and equal edge to edge air speed performance is achieved. Slot type nozzle applications are available for coating applications and finishing operations on the fabrics with high pile; and different applications are specially manufactured for lower and upper nozzle distances.

Diameters of the nozzle holes and numbers of holes are designed with flow simulation analysis and calculations to achieve the most efficient air flow. Air speeds in the nozzle holes are tested in different conditions and equal edge to edge air speed performance is achieved. Slot type nozzle applications are available for coating applications and finishing operations on the fabrics with high pile; and different applications are specially manufactured for lower and upper nozzle distances.

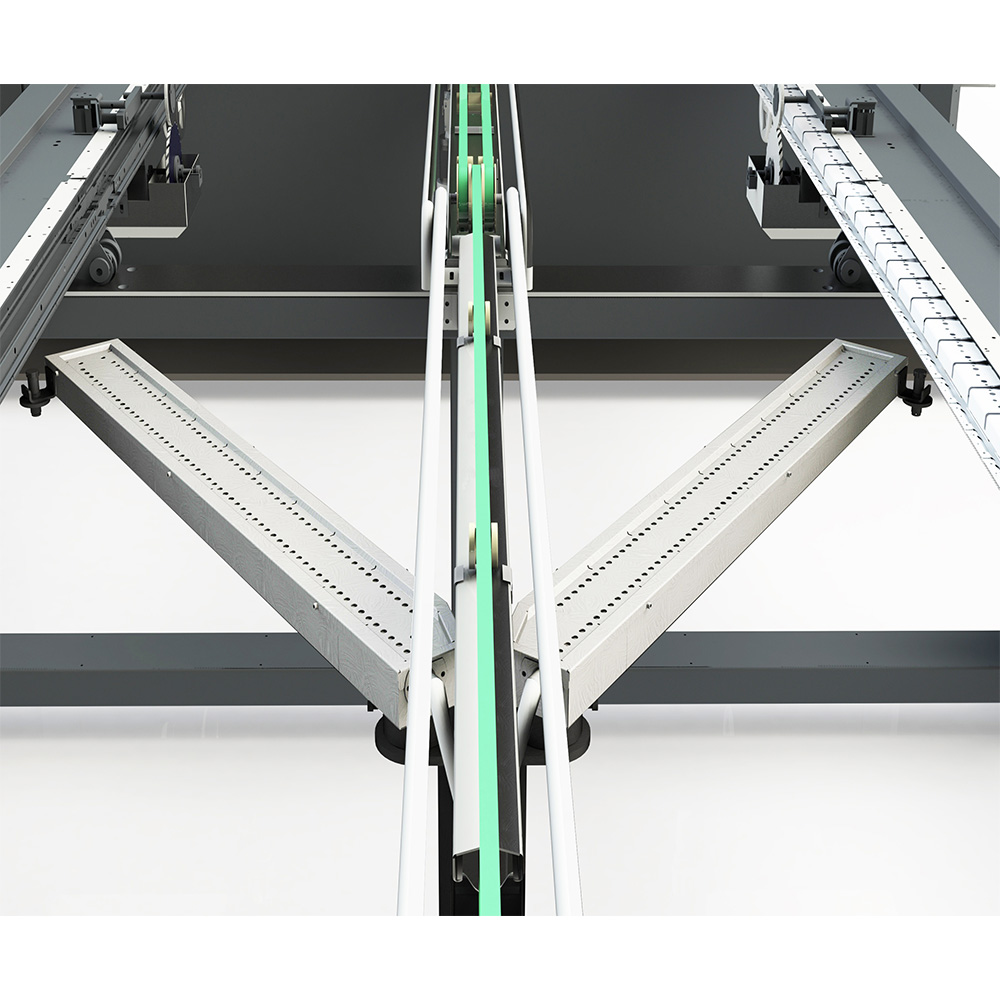

Fabric width control can be gradually increased and decreased (5% - 10% according to the type of the fabric) between the chambers thanks to the width adjustment spindles on one in two chambers or on each chamber according to customers demand.

Fabric width control can be gradually increased and decreased (5% - 10% according to the type of the fabric) between the chambers thanks to the width adjustment spindles on one in two chambers or on each chamber according to customers demand.

SER STENTER series; are the machines, each point of which is manufactured carefully, to provide the most efficient operational productivity possible with low energy expenses for finishing operations on the textile products.

SER STENTER series; are the machines, each point of which is manufactured carefully, to provide the most efficient operational productivity possible with low energy expenses for finishing operations on the textile products. Unique chamber isolation feature, cross fan which is designed to achieve efficient us eh eoaft and homogenous air flow – provides energy saving and capacity increase in production between 8% - 15% compared to the traditional machines.

Unique chamber isolation feature, cross fan which is designed to achieve efficient us eh eoaft and homogenous air flow – provides energy saving and capacity increase in production between 8% - 15% compared to the traditional machines. Thanks toth e heating and caiirrc ulation sections, which are placed crossly at intervals of three meters, higher air circulation gain and homogenous drying performance is achieved.

Thanks toth e heating and caiirrc ulation sections, which are placed crossly at intervals of three meters, higher air circulation gain and homogenous drying performance is achieved. Independent air-flow system is achieved through PLC control thanks to two inverters and four fans in each chamber. Air flow in the lower and upper nozzles is independently controlled through two inverters. This way, desired fixing and feeding value is achieved on even the most

delicate fabrics.

Independent air-flow system is achieved through PLC control thanks to two inverters and four fans in each chamber. Air flow in the lower and upper nozzles is independently controlled through two inverters. This way, desired fixing and feeding value is achieved on even the most

delicate fabrics.

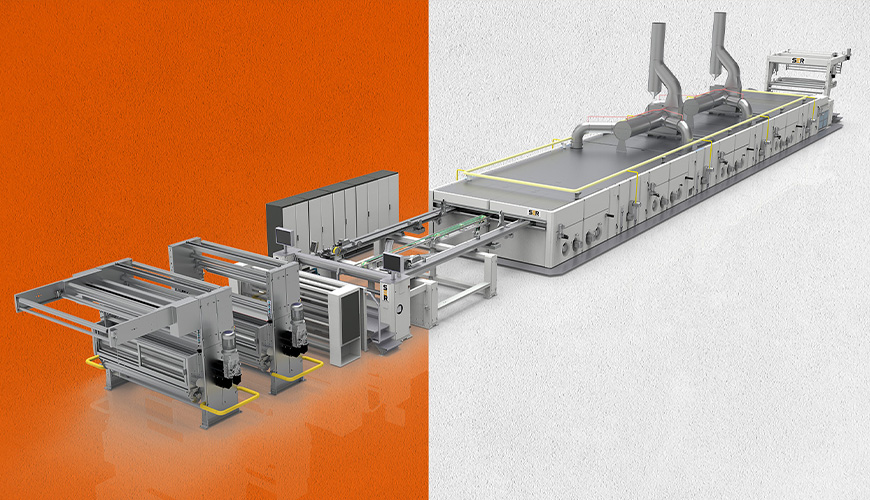

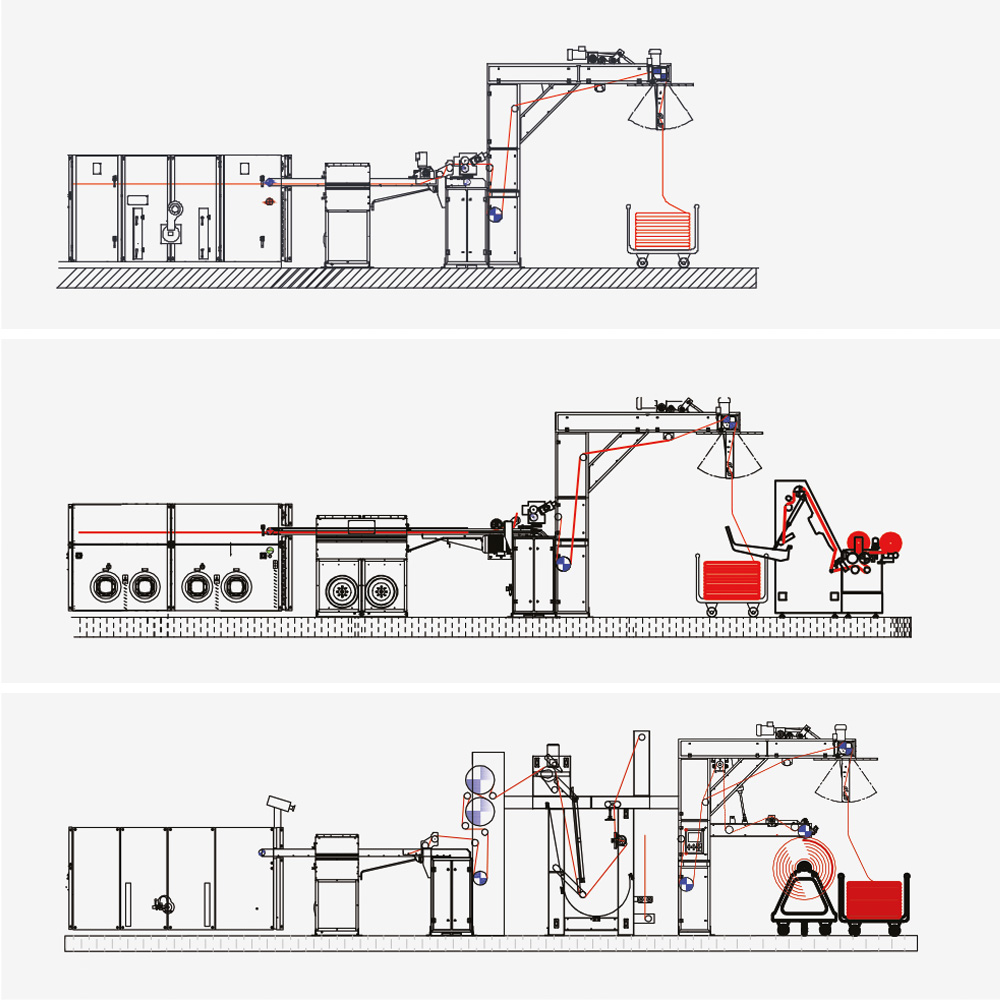

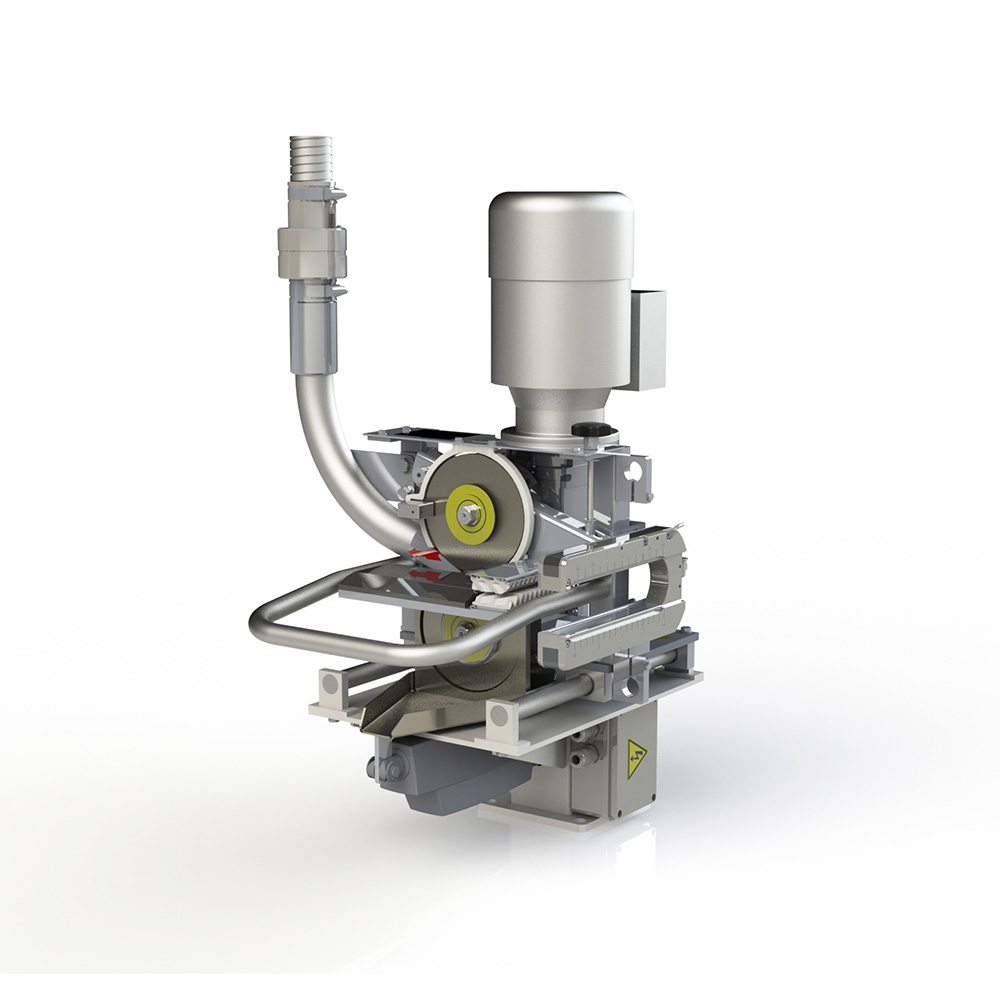

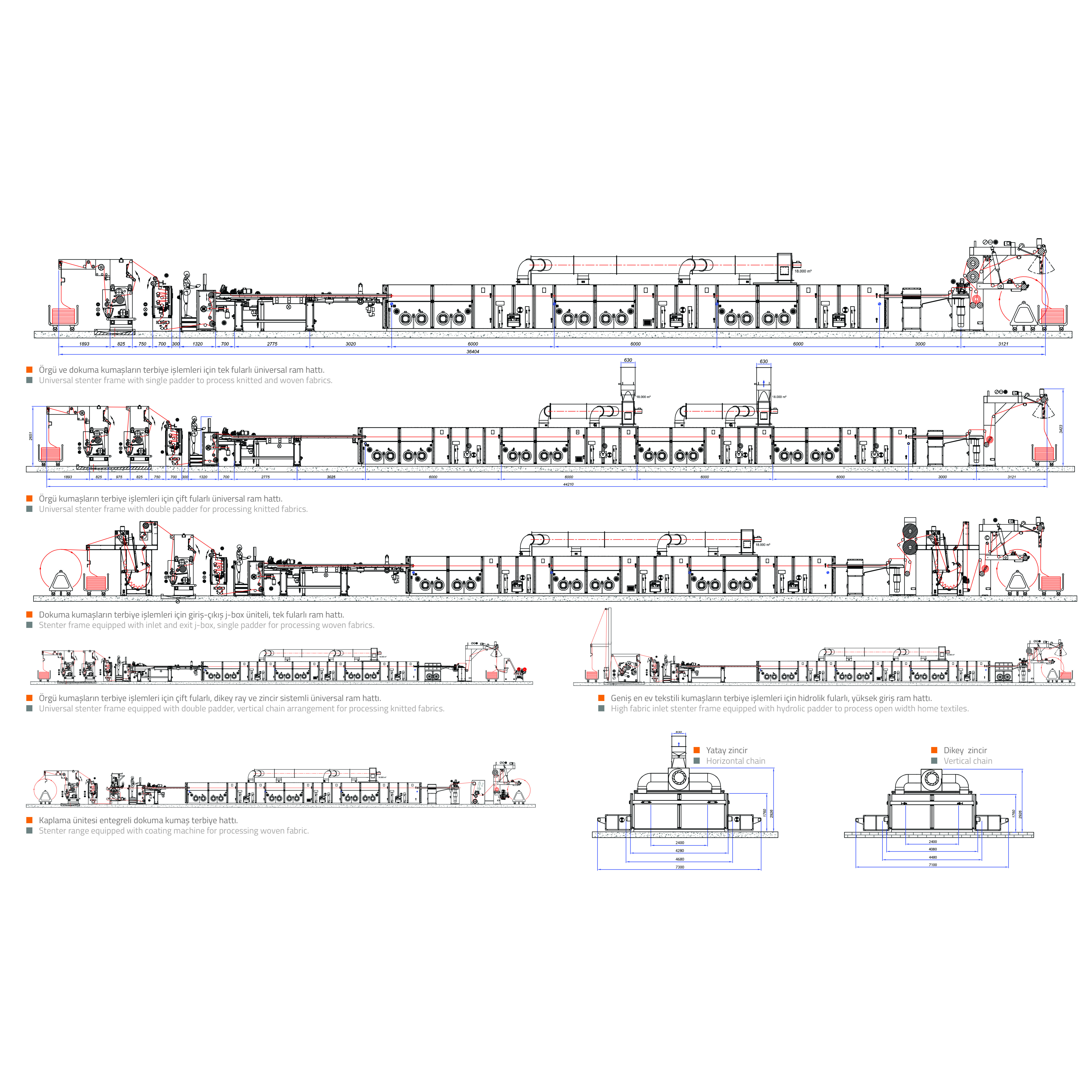

Inlet Units

SER STENTER serisi ram makinesinde örme ve dokuma kumaşlar, teknik tekstil ve kaplama sistemleri için farklı giriş, çıkış üniteleri mevcuttur.

Single foulard, double foulard, high input, batcher unwinding, centrally driven batcher unwinding and for non-stop fabric working possibility, J-box and accumulator inlet options are available.

SER STENTER series stenter machine includes different inlet and outlet units for knitted and woven fabrics, technical textile and coating systems.